Hatchery vaccination is increasing significantly and is becoming a very important practice for the poultry industry for the control of several economically important poultry diseases, such as Coccidiosis.

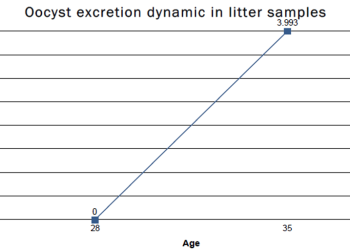

Hatcheries have been shown to be one of the main application locations for coccidiosis vaccines. And especially coarse spray method is widely used due to its efficiency to achieve the oral in-take of the coccidia vaccine droplets by the birds (Williams, 2002). The main objective of administering the coccidiosis vaccine in the early life is to allow the attenuated by precociousness oocysts to replicate before than wild oocysts in farm level (November, 2021).

In addition to early prevention, hatchery vaccination offers other important advantages such as the reliability of a full dose application, hygiene conditions, fewer vaccination errors, an automatized way of administering the vaccine and a quick method to administer a vaccine in large number of birds (March, 2017).

All these advantages should help to promote flock health, performance and a higher efficiency but principally when proper monitoring and control of all vaccine-related operations are implemented.

To support poultry companies in ensuring this, HIPRA has developed a series of services included under the new GLOBAL HATCHERY HEALTH PROGRAMME (GHHP) that will bring innovation and real-time control of the HEALTH of the hatchery.

GHHP consists of a range of distinctive services divided into three main blocks:

1. Optimization of vaccination procedures

GHHP offers services focused on guaranteeing correct vaccination procedures for all administration routes (coarse spray in the case of Coccidiosis vaccines, including innovative devices and the Smart Vaccination concept for vaccine verification through traceability.

Ensuring correct vaccination to reduce procedure failures and, consequently, to achieve better safety and efficacy of vaccination.

2. DOC quality control

Chick quality and vaccination quality are intrinsically linked, and one cannot be successful without the other. For this reason, GHHP is aimed at guaranteeing that the chicks leave the hatchery in the best condition thanks to DOC quality assessment through numerical and objective data:

- Physical evaluation: based on the PAS REFORM “Pasgar Score” test , a formula that allows chick quality to be assessed with a numerical value.

- Microbiological evaluation: the evaluation of the microbiological quality that works like a barometer of the processes associated with the breeders and the biosecurity of the hatchery.

This approach provides the possibility of anticipating challenges at field level.

3. KPI analysis

GHHP includes data science analysis (powered by HIPRASTATS®) to assess the key performance indicators at the hatchery level and to transform data into useful information to improve the decision-making process.

This service allows an in-depth analysis of the main variable factors that can affect final hatchability and 1st week mortality.

Through all these evaluations, critical points can be detected more easily, and this can help the hatchery team take better decisions. So, what benefits does this programme bring?

- Unique real-time vaccination control through traceability.

- Anticipation of field challenges.

- Detection of areas of improvement through the hatchery’s data.

- Savings in time and money by making the most of the vaccination process.

REFERENCES:

- Pas Reform – Hatchery Talks® Pasgar Score.

- Williams R.B., 2002. Anticoccidial vaccines for broiler chickens: pathway to success. Avian Pathol. 31 (4), 317-353.